This building tool is rather anti-building. The fact is that with the help of nail pullers they do not build, but break. It is intended primarily for disassembling fixed joints of wooden structures made with nails. At the same time, with the help of a nail puller, you can also perform other dismantling work: beating off plaster, dismantling brick walls, and much more.

This building tool is rather anti-building. The fact is that with the help of nail pullers they do not build, but break. It is intended primarily for disassembling fixed joints of wooden structures made with nails. At the same time, with the help of a nail puller, you can also perform other dismantling work: beating off plaster, dismantling brick walls, and much more.

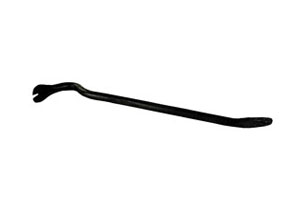

Nail pullers come in a wide variety of designs, but they all have a common feature. At least one of their ends has a flattened area in the form of a narrow blade with a widening slot. When pulling out the nails, the upper part of the protruding nail is inserted into this slot and using the nail puller as a lever, resting against the nail head, it is easy to pull it out. In hardware stores you can find a very large variety of nail pullers and we want to talk about all of them.

Types of nail pullers

crowbar nail puller

This tool is a classic nail puller tool. It is made entirely of steel. Structurally, it is a piece of steel rod, the ends of which are bent in different directions, and one or both of them are flattened and slots are made in them for pulling out nails. Along the length of the crowbar, the nail puller can be either of a small length - 40 cm, or very significant - up to 1.5 meters. Accordingly, the longer the nail puller, the thicker and stronger it is.

Previously, these tools were usually made independently from improvised materials. Usually, various shafts from mechanisms and machines were used for these purposes. If you see such a homemade nail puller - take it without hesitation. The fact is that this is a truly eternal tool due to the very high strength qualities of the material used. All the same, the shafts are made of high-strength steel. They used to make nail pullers usually familiar from factories that had access to powerful presses, or in forges that can be found in the vastness of Russia at the present time.

Those crowbars - nail pullers, which are now sold in stores, are of course worse. First of all, this is due to the fact that standard rolled metal products are used for their production. Currently, for the production of crowbars - nail pullers, reinforcement, a round bar or a hexagonal bar with a diameter of 10 mm to 25 mm are used. Despite the fact that some manufacturers still harden the ends, this tool wears out quickly and is easy to bend if you try to break a powerful building structure.

As an example, I will give my own experience - as a result of using a small modern nail puller, the slot developed to such a state that the nail heads in it simply stopped holding within two days. And this is taking into account the fact that with it I pulled out only about 1500 nails 30 mm long from the wooden floor (I tore off the old fiberboard).

Nail pullers made of reinforcement are a little stronger, but they can very quickly rub calluses on your hands if you do not wrap the handle with electrical tape, for example. Round and hex rod nail pullers are approximately equal in strength. Checking the strength of a nail puller is easy enough. Take a nail approximately 120 - 150 mm long and try to scratch the working part of the tool (slotted blade) with the tip. If the scratch turned out, and even deep, do not take this nail puller. There will be little sense from him.

hammer nail puller

Coming up with this design, manufacturers first of all took care to give the tool versatility. So two tools in one. Structurally, this is a classic hammer, usually with a rounded head, the sharp part of which is made in the form of a working part of a nail puller. On the one hand, of course, this is convenient, especially if you are sitting on the top of the roof, hammering nails and it took you to pull out one nail, which was bent from an unsuccessful blow.

At the same time, it is inconvenient to use a nail puller as a dismantling tool. It is not always possible with its help to crawl under the head of a nail, and it also has a less durable handle - made of wood, and the lever is much shorter than that of a crowbar - a nail puller.

As a material for the metal part of hammers of this type, forged tool steel is usually used, which usually surpasses the material of modern classical nail pullers in strength. On sale you can also find a tool of this type completely made of metal with an ergonomic rubberized handle. Hammers - nail pullers are usually used in plumbing and carpentry.

As recommendations, we advise you to have three types of nail puller in your tool kit: a hammer - a nail puller, a small classic nail puller 40 - 50 cm long and a powerful crowbar - a nail puller at least 90 cm long. The hammer can be used in construction work when you need to pull out one or more unsuccessfully hammered nails, with the help of a small nail puller it is convenient to pull out upholstery studs and remove the lining, but a large tool will be needed when dismantling powerful building structures, pulling out large nails or staples, as well as dismantling brickwork.

Other hand carpentry tools

|

Useful articles |