Any home workshop, in our opinion, should have not only a large set of hand and power tools, but also a couple of small machines, as well as stationary fixtures. One such device is a vise. This tool is designed to fix the workpiece in a stationary state, for greater convenience. Depending on the size of the part and its material, the vise comes in a variety of types.

Any home workshop, in our opinion, should have not only a large set of hand and power tools, but also a couple of small machines, as well as stationary fixtures. One such device is a vise. This tool is designed to fix the workpiece in a stationary state, for greater convenience. Depending on the size of the part and its material, the vise comes in a variety of types.

The largest vices are used in forges and are called chair vices. Smaller vices are called parallel vices, they are most common among ordinary citizens in garages and home workshops. For people who need to process a small part, a hand vise is suitable. In order for you to better understand the variety of locksmith vices, their properties and purpose, we will describe each type separately.

Types of locksmith vise

1. Chair vise. This type of locksmith vice is currently not very common, since its main purpose is to fix massive metal parts for further processing. Basically, these vices are used in forges. The chair vice got its name due to the fact that it is fixed on a massive wooden base called a chair.

A feature of these vices is that they are very large in size. By design, they are two symmetrical parts with jaws, interconnected by a non-rigid structure with a return plate. The parts are clamped by a massive screw mechanism with a handle. The vise is attached to the chair with the jaws up, so that the fixed part can be conveniently processed. Typically, in these vices, such work is carried out with details as riveting, metal cutting, and various bending works. Chair vise and strong carbon steel are made.

Chair vices come in a variety of sizes, but the most common sizes of these vise jaws are 100mm, 130mm, 150mm and 180mm. For ease of use and to reduce the wear rate of the tool, tool steel linings are installed on the working part of the jaws. To prevent the parts from slipping in the sponges during their processing, the overlays are cross-shaped notched, which increases the friction of the overlays on the part and does not allow it to move.

Despite the simplicity of the design, these vices have the greatest strength among other types. Among the shortcomings of these vices, their large weight and stationary location should be noted, which creates inconvenience if they need to be moved from place to place. Also, due to the special design of the jaws, narrow parts, or vice versa, very wide ones, are not very convenient to clamp in this vise.

Due to the peculiarities of the clamping mechanism, the clamping plane is much smaller than the total area of the jaws, or rather their overlays. Well, due to its power in this type of vice, if you do not calculate the clamping force, you can easily damage the part by hushing its surface.

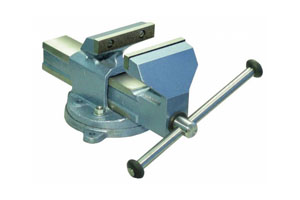

2. Parallel vise

This type of vice is the most common in everyday life. They are called parallel because of their special design. The fact is that one of their sponges is constantly in a stationary state, and the second one moves along the guide with the help of a screw, while the sponges are always parallel relative to each other. To begin with, we note that these vices are divided into two subspecies: swivel and non-swivel.

- swivel parallel vise due to its design have the ability to rotate to any arbitrary angle relative to the installation site. This is very convenient, since you do not need to approach the part yourself. Taking into account the fact that metalwork vices are usually installed on a workbench, which is located near the wall, it is often physically impossible to approach from the right side and you have to process the part in an uncomfortable position.

In order to be able to rotate the vise and fix the tool in a stationary state, its design provides for a swivel mechanism and a clamping screw. If we talk about the size of this type of vise, then in stores you can find them with jaws in sizes of 80 mm, 100 mm, 120 mm and 140 mm.

- non-rotatable parallel vices do not have the ability to turn them in different directions. The body of this vise is made entirely and is screwed tightly to the workbench. However, due to the simpler design, the fixed vise is much less expensive.

Given the fact that most people do not need such a bells and whistles as a swivel mechanism, they opt for a non-swivel parallel vice. In terms of size, this type of vice practically coincides with the rotary ones. The width of the jaws of this type of vise is 60 mm, 80 mm, 100 mm, 120 mm and 140 mm.

Cast iron is usually used as a material for the manufacture of parallel vices.

3. Hand vise

In terms of size, this type of vice is the smallest. In stores you can find this type of vise with jaw widths of 36 mm, 40 mm, 50 mm and 56 mm. These vices are intended for small jobs, when it is necessary to fix a small part for its processing. According to the design of the clamping parts, this type of vice resembles a chair vice, but of a small size. During operation, the vise is held in one hand, while the other performs work on processing the fixed part. Hand vise is made of carbon steel grade 45 - 50.

Other hand tools

|

Useful articles |