In villages and villages a couple of decades ago, almost any owner of a private house in a garage or barn had such an interesting and wonderful tool as a blowtorch. In terms of its usefulness, this tool was perhaps not inferior to such more popular tools as an ax or pliers.

In villages and villages a couple of decades ago, almost any owner of a private house in a garage or barn had such an interesting and wonderful tool as a blowtorch. In terms of its usefulness, this tool was perhaps not inferior to such more popular tools as an ax or pliers.

This was due to the fact that a lot of problems could be solved only with its help. They used a blowtorch to heat locks on doors, frozen pipes, dry surfaces made of non-combustible materials, but most importantly, they burned piglets - then they were in almost every yard. Now, of course, there is not so much work for this lamp, but still it is a fairly useful tool in the household. And now in more detail about its design, features and purpose.

The history of the blowtorch

If we consider the history of the creation of a blowtorch, then this happened back in 1881 in Sweden. The scientist Carl Gicard Nurberg then invented a device in which a combustible substance, which could be kerosene, alcohol or gasoline, was transferred to a gaseous state in a lamp, after which the vapors burned out forming a stream of fire.

Oxygen for combustion of these vapors came from the surrounding air. At the same time, a jet of vapor from the nozzle, as it were, pulled the surrounding air into the combustion area, which ensured a stable stream of fire. Over time, of course, blowtorches improved, but all the physical principles have remained the same since then. So we can say that in the modern world we use almost the same lamp as our ancestors used more than 100 years ago.

Scope of blowtorch

Partially about the use of a blowtorch was described in the introductory part of the article, but we will also talk about other methods. You can also use a blowtorch:

- to soften the paint (with its help it is convenient to soften the old paint on various surfaces. Here the lamp acts as a thermal gun, which not everyone has lying around in construction tools, and it costs much more and does not have such autonomy, as it requires connection to the mains) ;

- for thawing frozen water pipes (if the pipes with water are frozen, then with the indicated tool it is very convenient to melt the ice in the pipes, due to the large heat transfer);

- for thawing frozen padlocks on a garage or shed (similar to the previous paragraph);

- for disassembling rusty threaded connections (due to the heating of metal threaded connections, they expand and, as it were, break the rust. Also, due to heating, the distance between the nut and the thread on the pipe increases. Therefore, after heating, unscrewing is much easier);

- for kindling fires and cooking (when camping, on a picnic or far from home, you can easily kindle a fire with a blowtorch even if the wood is not very dry, and also cook food by directing the fire to a pot or cauldron - the main thing is that they are metal);

- for heating liquids (if you direct the lamp fire at the wall of a metal tank with water and wait for a while, you will get hot water for various needs without much difficulty even in the cold season);

with water and wait for a while, you will get hot water for various needs without much difficulty even in the cold season);

- for melting various bitumen, mastics and resins (during construction work, it often becomes necessary to heat resins and bitumens to a liquid state. Doing this with a blowtorch is much faster than making a fire. Also, a blowtorch is useful when gluing material such as glass isol, when one side needs to be heated).

- to warm up the oil in the crankcase of a car engine or bridges (often this is the fastest and only way to start a car after a long standing in a frost of more than 30 degrees).

- to warm up the oil in the crankcase of a car engine or bridges (often this is the fastest and only way to start a car after a long standing in a frost of more than 30 degrees).

Blowtorch design

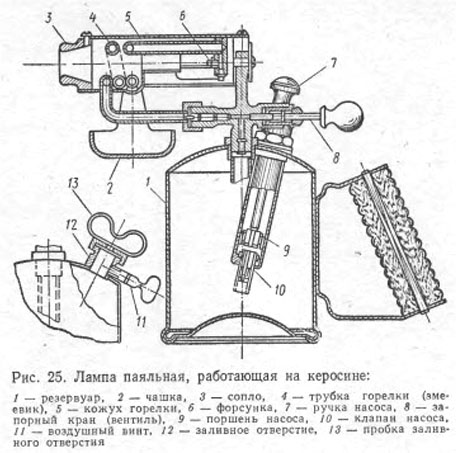

A standard gasoline blowtorch is a body that is used as a fuel reservoir, on which all elements of the lamp are fixed along with a handle.

In fact, in addition to the body with a handle, the blowtorch design includes:

- a pump with a valve (for pumping air and pressurizing the lamp);

- siphon tube (fuel is supplied through it to the evaporator);

- evaporator (for transferring fuel into a vapor state);

- needle valve (for adjusting the intensity of fuel supply);

- nozzle (an element through which fuel is supplied to the combustion area);

- a filler neck with a cap (fuel is poured through it);

- a wire for cleaning the nozzle (needed to clean the nozzle from burning that settles in the nozzle).

The blowtorch works very simply. Inside we fill in fuel - gasoline, after which we close the neck with a cap with a screw and a seal. Next, using a hand pump, we pump air inside to create high pressure inside. Next, open the nozzle a little so that a small stream of fuel splashes out and ignites it. After the fuel has caught fire, increase the fuel supply (we open the nozzle more strongly). Due to this, the speed of fuel exit through the nozzle increases and it is more sprayed.

Accordingly, we get not a jet of gasoline, but a jet of vapors, which, when burned, form a jet of fire. It is necessary to adjust the nozzle in such a way that gasoline burns quickly and completely at a short distance. This may be indicated by the peculiar noise of the flame of the lamp.

At the end of the article, we note that, of course, the industry produces blowtorches of various types (depending on fuel):

- gasoline;

- gas;

- kerosene;

- alcohol.

Accordingly, they are quite different in design. We described in our article exactly the classic version of a gasoline blowtorch as the most common.

Other hand tools

|

Useful articles |